I have heard many times from someone who just wants to start sewing: “I have a brand new sewing machine, but I have no idea where to start!”. Well, we start at the beginning, don’t we? Therefore in this tutorial, I will show you how to start working with a sewing machine. If this cute ball of fluff is not scared of the big bad sewing machine, neither should we be!

When I got my first computerized sewing machine, I was very excited and enthusiastic for a few minutes until I realized that I have no idea how to use it. So many controls and buttons! If I touch that, can I break it? Can I press this lever? I certainly couldn’t operate it without learning first. So, I started to study the manual. I noticed pretty soon that it is not as complicated to learn as it might seem. Machines make sewing fast and easy and taking the time to learn what they can do and how will pay off in the end.

For this tutorial, you will need

- a sewing machine

- a manual for your sewing machine (if you don’t have one, look online, also they usually sell manuals for older machines on eBay, but you have to know your brand and model exactly)

- few pieces of fabric to practice (1. Medium weight cotton. 2. Silk. 3. Denim or thick wool), just solid colors without any prints

- sewing machine needles (universal, different sizes)

- few spools of threads of different colors and sizes (contrast to the color of your fabric)

- scissors for cutting threads

- an iron

- sewing machine accessories (any sewing machine usually comes with some standard accessories, like different presser feet, sets of needles and bobbins, screwdrivers, etc.)

And here is the plan of how we are going to proceed

- Find the manual / instruction book for your sewing machine

- Look at your sewing machine and try to learn some of its parts using your manual

- Sew along some lines on a piece of tissue paper (only with a needle without threading the machine)

- Learn to change the needle using your manual

- Thread your sewing machine

- Wind the bobbin and draw up the bobbin thread

- Start sewing straight stitch

- Learn to adjust your machine settings

- Use some additional tips for sewing straight stitch

- Try to sew a zigzag stitch

- Try to sew two labyrinths – one is square, and the other is round

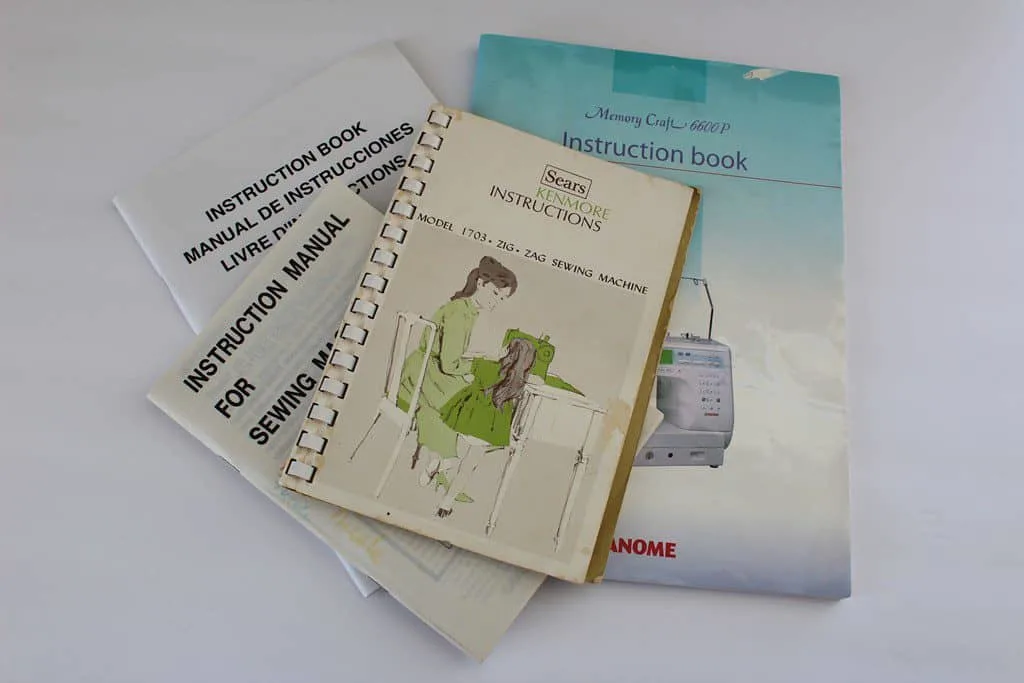

1. Find the manual / instruction book for your sewing machine

If you use an old sewing machine it may be a problem to find the manual for it at home. Look online for your brand and model. In most cases, you will find it on eBay.

Also, many manufacturers have support sites where manuals for some models are available, most of the time for free. Or join one of the sewing Facebook groups and ask others – I have created such a group which can be reached here. But I recommend that somehow you find a manual for your machine. The more complex your machine is, the more necessary the manual becomes. It will have part numbers for items that can break, maintenance tips and schedules, procedures specific to your machine, how-to tips, etc.

Usually, people only read the manual as a last resort. Remember the phrase: “When all else fails read the manual”. But it often means the difference between a capable and confident user who gets the most out of the sewing machine and one who is wary, hesitant, and limited.

Be prepared though that manuals are usually very technical, often hard to follow, and tend to bury the necessary information among collections of safety warnings.

When you open your manual, you will usually see first something like this: READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE. But I bet, you have already turned it on and fiddled with the buttons, and lived to talk about it. And now you have a question in your head: What, do I need to read these 100 pages of books instead of going to my phone screen?

Manufacturers have to place warnings because of liability issues and the funny thing is, I bet those warnings stem from someone actually DOING the things they warn about! It is not a bad idea to read those warnings, and certainly to make sure you talk to your children about them.

Manuals can also be large. I hope you can work it out and it will be not too hard to find what you need to know in the beginning. Treat your manual as a cookbook – find “the recipe” you need at this point and ignore the rest till next time. I guarantee you that in time you will read every page.

Each brand of a sewing machine has its own design and specifications. That’s why I can’t give you an exact guide about the function buttons of your model, threading your machine, winding the bobbin, balancing thread tension, selecting the sewing mode, and other specific machine settings. These details you will find in your manual. And my task is to guide you so you are not burdened with all the information and can start using your machine right away.

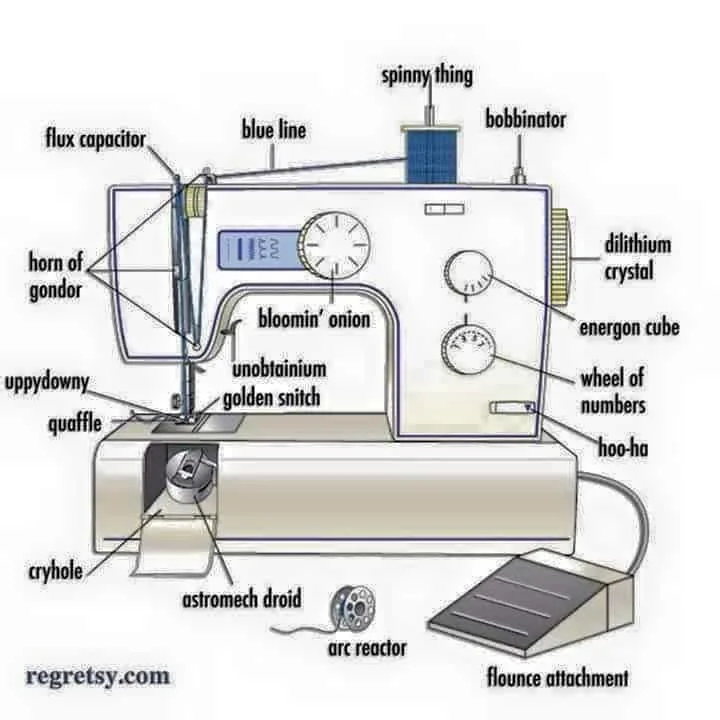

2. Look at your sewing machine and try to understand ITS PARTS

Let’s start with a joke I found on the Internet: the “Sewing machine TNG“. There is nevertheless a little truth in this: the sewing machine, especially a computer-driven one, can be a complex piece of machinery. What do you think?

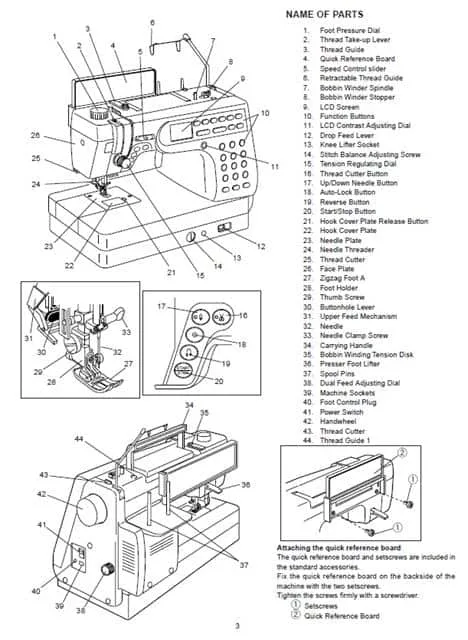

As with any device, sewing machines have specific parts, named with characteristic terms. The manual will have in the beginning a list of all parts with images showing where they are; you need to identify them because throughout the manual there will be references to them. Here is what the first page of this description in the manual for my machine (Janome MC-6600) looks like:

The point is that if you develop good sewing habits from the start and learn about how a sewing machine works, you will be able to do your own troubleshooting when you start having trouble. And at some point, everyone has trouble.

There are hundreds of models and brands on the market but even if all machines are not made equal and they don’t have the same parts and performance, their basic functions are the same: they connect pieces of fabric together with an automated stitching mechanism, they require a continuous thread that runs from a spool pin on the top of the machine to be fed to the needle and this thread has to be connected with another thread from the bobbin.

The bobbin is just a small circular spool of thread located in a shuttle underneath the needle. The needle is fastened by a screw to the needle bar, which is driven up and down by the motor. The fabric, placed on a metal needle plate under the needle, is held down by a presser foot which is held by a presser bar.

The pressure can be adjusted for different weights of fabric. The Presser foot lifter raises and lowers the presser foot. There is the feed dogs mechanism which pulls the fabric forward every time the needle is pulled out of the fabric. The thread runs through the tightening arm and through a tension disc assembly. By turning the disc assembly, the sewer can tighten or loosen the thread going into the needle.

All sewing machines also have bobbin winders to fill bobbins with thread and hand wheels that move the needle. All machines produce a straight stitch – a simple stitch that binds fabric with a straight seam.

Other parts and functions differ from machine to machine. For example, some of them have electric foot controls and some of them work with just a small start/stop button.

Most modern home sewing machines are computerized and they can sew hundreds of different stitches. They have built-in computers, as well as visual displays for easier operation. Most controls are done by touching a button!

You will need to study your machine manual to know its parts, standard accessories, and controls. First of all, find out what the following are and where they are for your machine:

- presser-foot

- presser-foot lever/lifter

- needle screw

- needle plate

- cover plate

- feed dogs

- thread guides

- spool pins

- bobbin

- bobbin winder

- some control knobs: thread tension regulating knob, stitch length knob, and other function buttons specific to your model

3. Sew along some lines on a piece of tissue paper (only with a needle, without threading your machine)

It seems that making a straight line with a sewing machine is the easiest task. But it is not as simple as it seems. Your hands are not used to hold the fabric properly, and the fabric wriggles, slides, and stretches under the needle. And in the end, your stitches which are supposed to be straight look crooked and distorted.

It is easier to learn how to sew exactly along the lines if you first start to sew on paper just with a needle without any thread. When you get even lines on paper, it will be much easier for you to cope with the fabric.

So, take some wrap tissue, fold it, and draw straight lines on it with a marker, something like on this photo. Now put this paper under a presser foot of your machine and start sewing along the lines.

Try altering the stitch length with the Stitch length adjusting button. Try to control the sewing speed on your machine. When you need to change sewing direction, stop the machine with the needle lowered down into the paper, raise the presser foot, turn the paper around the needle, lower the foot and continue sewing.

After sewing on paper, your needle will become blunt. So you will need to change the needle before doing any sewing on fabric.

4. Learn to change the needle using your manual

For this, you will usually need to loosen the screw that holds the needle and take it out. Then of course place the new one in and tighten the screw. The following short video shows how simple this operation is however we must pay attention that the needle is properly positioned and screwed in well or when the machine starts the wobbling needle will break and mat damage other things around.

When inserting a new needle make sure that the flat side of the needle goes to the rear. Tighten the needle screw firmly. Never use a blunt needle.

The needle size has to match the thickness of the fabric and the thread you use for your project.

Check whether the needle passes without obstacles through the hole of the needle plate, whether the needle is sharp, and whether it is bent or even broken. For this tutorial, we will use universal needles sizes 80/12 and 90/14.

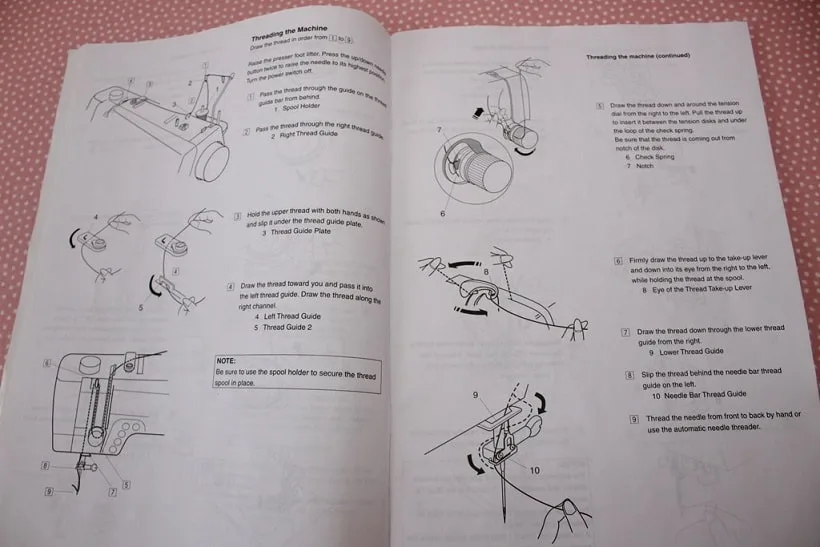

5. Thread your machine

Each sewing machine is a little different but the principle is the same – the thread has to go through a few eyelets and a tension disk before it goes to the needle.

The sequence of draws is very important and can be found in your manual. You can’t ignore the order, or you may end up with a broken thread, needle, or even the whole machine. For example, the manual for my sewing machine has very detailed instructions about threading the machine.

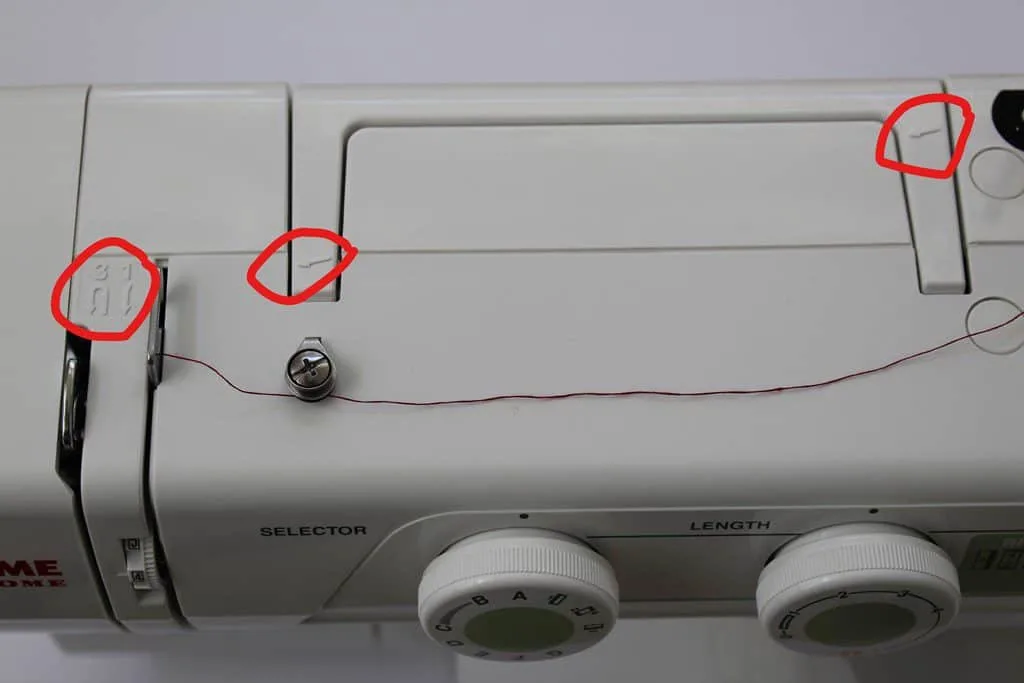

Many new machines have lines and arrows designed to help you to do threading correctly. So look at your machine. Do you see a diagram printed on the machine itself, or signs to help with threading, like in the images above?

Presser foot lifter must be raised and the needle has to be in its highest position before the threading procedure.

Place the thread on a spool pin and draw the thread through the upper thread guide – a metal part sticking out at the top. The thread must go down through the tension disk and return up to the second thread guide. Thus, the thread will pass the path in the form of a letter U. After this, it must go through the second thread guide at the top and be drawn down to the needle. Insert the thread into the small hole at the bottom of the needle from front to back by hand or use an automatic needle threader if your sewing machine has one. Then the thread must be drawn under the presser foot, located directly under the needle.

VERY IMPORTANT: the power switch should be off. Otherwise, you may be injured if you accidentally press the pedal or push the start button when your fingers are under the needle.

I have dedicated a full article to this, perhaps you can check it out: How to thread a needle on a sewing machine

6. Wind the bobbin and draw up the bobbin thread

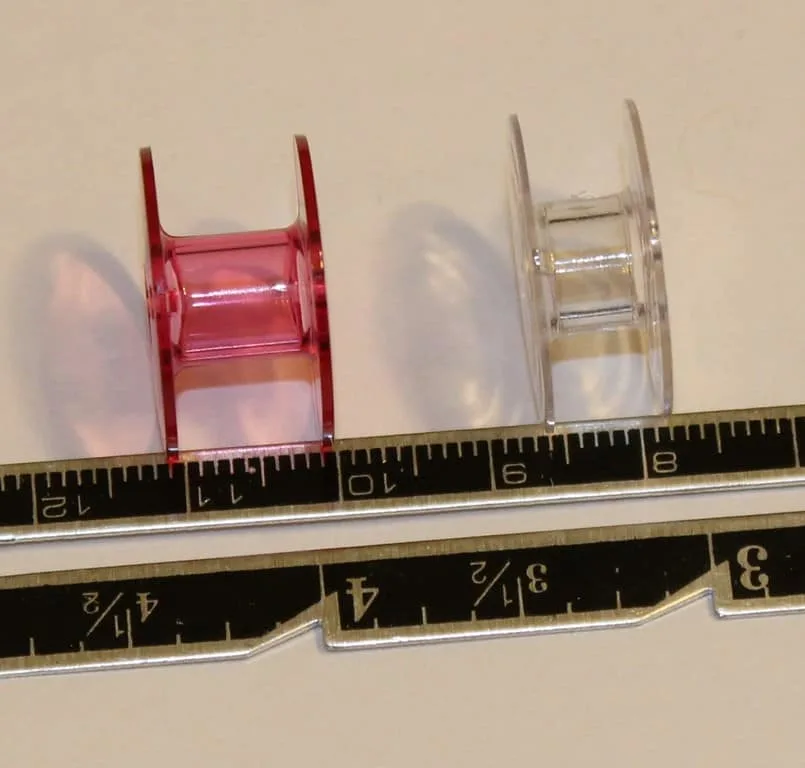

It’s very important to use the same type and size of thread you put in the needle.

For sewing projects, they have to be the same color. But for test sewing, we choose different colors of threads so you can see better how threads connect with each other in stitches.

For sewing projects, they have to be the same color. But for test sewing, we choose different colors of threads so you can see better how threads connect with each other in stitches.

Have in mind that bobbins vary in size on different machines. So if you need to buy new bobbins for your projects choose exactly the same size bobbins you have inside your machine. They can be plastic or metal.

Draw the thread from the spool through the bobbin winder tension disk.

Pull the thread through the hole in the bobbin. Place the bobbin onto the bobbin winder pin and lock the latch against the bobbin until it clicks. Start the machine. Wind the thread until the latch releases, and remove the bobbin.

Bobbin winding should be balanced. If your machine is doing it incorrectly, hold the thread with your hand and manually direct it onto the bobbin. Notice in the following video how I guide the thread manually to fill the bobbin equally. Do not pull the thread by hand, leave the thread as free as possible, and just guide it.

On older and simpler machines bobbins usually fit in a metal bobbin case but in most modern machines bobbins are just put under the needle plate right in the shuttle without any case. The following images show both situations. Make sure you always set the bobbin properly in its case (according to the manual) and also make sure the bobbin case is clean.

If somehow the winding mechanism is broken on your machine or you do not want to use an expensive piece of equipment for such a simple task you can buy a special bobbin winder. It looks like this.

Or you can buy pre-wound bobbins; they are sold in cases like in the image here. But make sure the size of the bobbins matches your sewing machine and the threads are good for your purpose. I buy pre-wound bobbins usually with the most used colors like black or white.

For sewing, you need to bring the bobbin thread up from underneath the needle plate. For this raise the presser bar lifter and while holding the needle thread with your finger, move the needle down and then up to bring up the bobbin thread. Slide 4 in (10 cm) of both threads to the back under the presser foot. The short video below shows the bobbin is inserted into the machine and then the thread being brought up; for this purpose, the cover for the bobbin case is left open. When you sew, the plastic cover over the bobbin would be closed.

The bobbin thread is not less important than the needle thread, I have dedicated another full article to it also: How to thread a bobbin

7. Start sewing straight stitch

We are ready now for the first real stitch. They say the beginning is always more difficult, but the following video shows this is really simple.

- Place a piece of cotton fabric under the presser foot with the bulk of the material to the left of the needle (use size 90/14). I used a piece of fabric folded in two and I urge you to use the same, the reason will become apparent later.

- Lower the needle into the fabric about ½ inches (1 – 1.5cm) from the beginning of the seam by turning the balance wheel manually (always turn it toward you). This makes sure the fabric does not move when you start sewing.

- Pull needle and bobbin threads toward the rear to avoid sewing over them. Lower the presser foot. Stitch 3-5 stitches in reverse to secure the thread’s ends. You see me in the video pressing the small lever on the right – that is the “reverse” switch on the machine I used. Complete the seam.

- When you reach the point you wish to stop, sew back in reverse 3-5 stitches again to fasten the seam.

Some notes:

- Do not stitch beyond the edge of the fabric. Cut off threads at each end of the stitching. All modern machines have a small steel ridge on the left side where you can cut the thread, or you can use scissors. Some machines even have automatic thread cutters but I avoid using that feature because I don’t usually need the thread cut every time I stop stitching.

- Try to run the machine at different speed settings.

- Always finish sewing with the needle at its highest point.

- Guide the fabric gently with your hand in front of the needle letting the fabric feed naturally. Never pull the fabric.

- Before and after stitching press the fabric so stitches are perfectly flat and smooth.

8. Learn to adjust your machine settings for the straight stitch

It can be so annoying when you need to stitch something and the machine does not sew correctly, breaks the needle, tears the thread, and tightens the fabric. The first adjustments you will need on the machine are the stitch length and the thread tension.

The most common problem is the incorrectly adjusted thread tension but adjusting it doesn’t mean that you have to rush to a service center. Usually, it is simple to make such adjustments and you will need to do that often, depending on the thread used (type and thickness), material, and stitch type. It is important to have at hand a manual and a lot of patience. Even the most expensive and high-quality sewing machine requires additional adjustments for different fabrics.

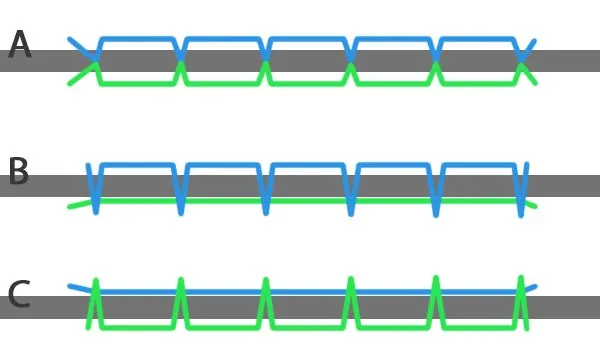

Find out in your manual where your machine has thread tension regulators or tension control knobs, and also the knob that sets the stitch length. You can adjust separately the upper thread tension (needle thread) and bobbin thread tension. We can say that stitches are good

- when it is clearly visible where one individual stitch ends and another begins,

- when the pattern is even, it does not jump,

- and ideally, if you flip the fabric, you should see exactly the same stitches on the other side

In books, they say that the correct straight stitch has threads locked between two layers of fabric. Picture A below is the ideal case. In picture B the thread tension is too loose (low) and in picture C the thread tension is too tight (high).

On medium weight and heavyweight fabrics if the stitch is correctly done you will only see one thread on each side: the needle thread on the upper side and the bobbin thread on the lower side; the loops (where the bobbin thread goes around the needle thread) will be hidden in the bulk of the fabric. On thin, sheer fabrics you will, however, see both threads since the fabric is not thick enough to hide the loops. This does not necessarily mean the stitch has problems, if the stitch is regular, even, tight, and without puckers then all is good.

What is “puckering”? Look at the image here; the stitch seems correct, but the material is bunching around the stitches and is no longer flat. This is actually a big problem and it may have multiple causes.

I have a video course that deals in detail with puckering and a set of printable sheets that present the phenomenon (and possible solutions) in my Etsy shop.

For now, suffice to say that if the puckering takes place on the UPPER side of the fabric, you need to lower (loosen) the thread tension a little. Conversely, if the puckering is on the LOWER side, you will need to increase (tighten) the thread tension. This is why I used a piece of fabric folded in two.

In the video below I am showing what is happening when the thread tension is set to zero (0). There are instances when you actually need to do that, but here I did it to show the very obvious puckering on the lower side:

Puckering can happen also for other reasons, and then the seam can have puckers on both sides. For example, when the foot pressure is not right for the fabric. Find in your manual if you can adjust the foot pressure. Not all machines are equipped with this control but if you have it, then it has to be stronger for thicker fabric than for fine lightweight, and elastic fabrics. Enough about puckering for now!

Also for the correct straight stitch, you have to choose the proper size of thread and needle, otherwise, you may end up with a weak seam (if the thread is too thin for the fabric) or perhaps large holes in the fabric (if the needle is too big and the fabric is thin).

Sometimes it takes a lot of time to adjust the machine setting, especially on “whimsical” fabrics: fleecy, stretching, very thin, and slippery. Be patient and don’t leave the settings as is. Any sewing machine is able to make the stitches perfect. You just need to adjust it properly. And here is another piece of advice that I will repeat frequently: ALWAYS test the seam on scrap fabric before using it in the project.

Straight stitch can have variable lengths. It can be altered by moving the stitch length adjusting knob. For thin fabric and thread, it is smaller, for thicker fabric and thread it is bigger. The standard length is usually between 2 and 3 mm. For thin fabric it should be around 2 mm, for thick fabric – at least 3 mm. Now, after we used cotton fabric, let’s try to sew fine silk and thick wool.

First, sew them without any changes. Do you see any difference in the quality of stitches? Any broken threads or needles? Skipped stitches? Seam puckering? If you see some problems ( you will see them for sure) change the needle. For fine silk, it should be thinner, 80/12 or 70/10 and for thick coat wool, it may be bigger 100/16. Also, adjust the thread tension and sew again till you are satisfied.

9. Additional tips for sewing straight stitch

- Usually, before sewing with the machine, you need to baste pattern pieces by hand with running stitches to hold them together while you finish sewing them with permanent stitches. You have to stitch with the machine at a distance of 1mm from the basting line (less than 1/16 inch, which means very close to it). Try to not step with the machine on the basting thread as it will be difficult to take off temporary hand stitches. The videos below show the right and the wrong way to do it:

- Some professionals recommend basting pieces of fabric just with sewing pins without any running stitches. In this case, pins must be perpendicular to the sewing line (or to the seams) like in the below video:

- Put your machine in a comfortable bright place and take care of an additional light source if you will be sewing with artificial lighting in the evening.

- Clean your machine. After you finish sewing, wipe the machine, clean the bobbin case and remove the dust that has accumulated inside the shuttle, place a piece of cloth under the foot, lower the needle and close the machine with the cover.

- Very often the stitch has to be fixed with two or three hand stitches or the end of the upper thread may be pulled to the other (wrong) side and tied by hand like in the below video.

I have used the above notion of the “wrong side” of the fabric. It is not really WRONG. It is the side of the material that normally can not be seen when the garment (or whatever you make) is in normal use, the inner side. The side that is normally seen (the outer side) is of course the right side.

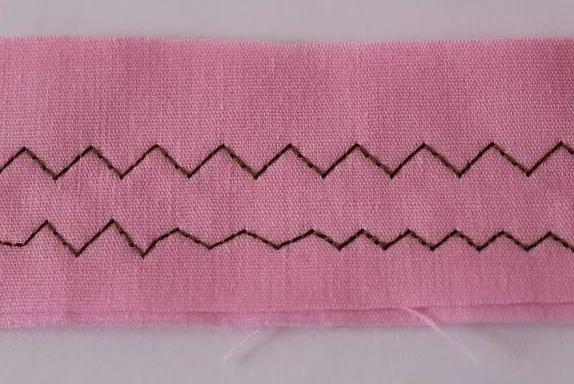

10. Try to sew a zigzag stitch

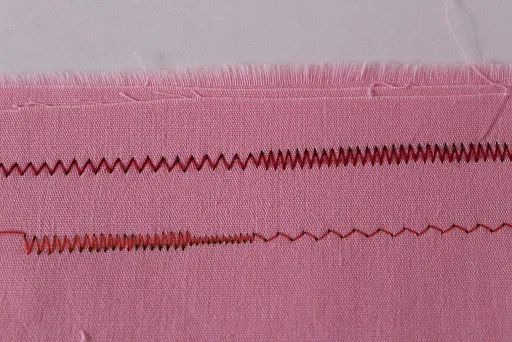

Zigzag stitching is widely used to prevent the fabric from fraying at raw edges. It is a very strong stitch that holds fabric together extra tight. It is hard to rip. A dense zigzag stitch can also be used for appliques. Set your machine to zigzag stitching using your manual. Sew a few stitches and try to change the zigzag length and width.

Correct tension of zigzag stitch is when the bobbin thread doesn’t show on the top side of the fabric and the needle thread shows slightly on the bottom side of the fabric. That’s what the bottom side of the fabric looks like:

Sometimes when you sew zigzag you may have a problem with the fabric puckering under the stitches. It can happen because the width of the zigzag stitch is too big for the fabric you use. So lower the length and try to sew again.

If the problem didn’t disappear set your machine to the different zigzag stitch which is called multiple zigzag or tricot stitch. It looks like a zigzag but with a dashed line and with three stitches per “zig”.

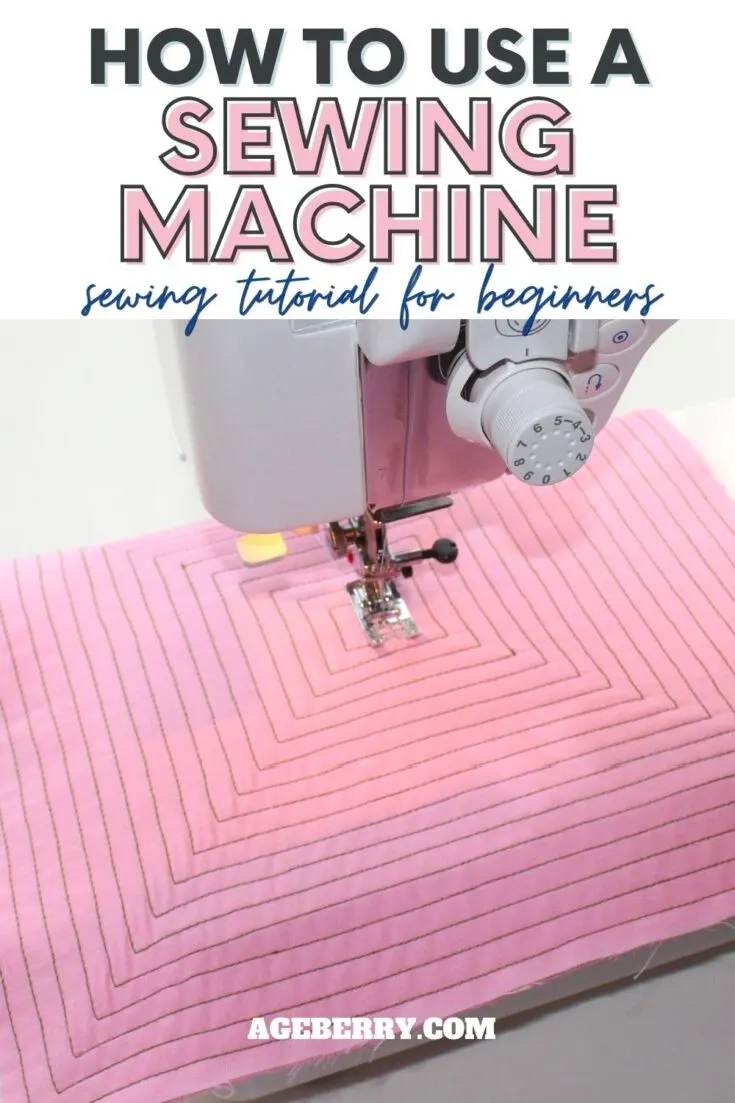

11. Try to sew two labyrinths, one square, and the other round

I would advise you to make some very useful “exercises”. Sew this labyrinth to improve your sewing skills

Prepare 4 square pieces of medium-weight cotton, 30 cm x 30 cm (12 in x 12 in). Baste every 2 pieces with a running stitch on all 4 sides.

Start sewing a square labyrinth in one of the outside corners, keeping a 0.75 cm ( about ¼ inch ) distance from the seam edge which is equal to the half-width of the presser foot of your machine. The right edge of your presser foot should be level with the fabric edge.

And focus on keeping the same distance between all rows of stitches. Choose the stitch length of 3 mm ( 1/8 inch ). Sew at lower speed and don’t rush through it. Don’t worry if not all stitches are perfect – this is an endurance test!

Your main problem will be stopping in the corners at the point which has the same distance to both stitching lines. When you reach the center through countless turns your sewing skills will be significantly improved.

After you complete this project sew a labyrinth in the circle on the other piece of cotton. Keep the same settings. Draw a small circle in the middle with some marker and start sewing along the line. In this case, your main problem will be the correct maneuvering of the fabric under the presser foot.

You will notice that after I finished the initial circle I went straight with the machine until the left edge of the foot touched the circle. At that point, I started to follow the circle making sure the left edge of the foot is as close to it as possible. What results is in fact a spiral-like in the video below. Good luck!

Now you have basic sewing machine skills but of course, you still need more practice. You will be surprised at how non-intimidating this stuff is once you just start to do it more often. And eventually, these practices become habits that you don’t even think about – you just do them automatically. Did you practice? How hard was it? Do you have any questions? Please, send me images of your labyrinths if you tried this.

Did you find this tutorial helpful? If so, save this pin (see below) on your sewing board so you can come to this tutorial later when you are ready to use a sewing machine, and follow me on Pinterest for more tips, tutorials, and inspiration!

latest posts

- Ditch My Sewing Machine? Not in This Lifetime!

- Adorable DIY Needle Book | Easy Tutorial for Beginners

- Master the Seam Ripper: Your Ultimate Guide to Precision Stitch Removal

- Think You Know Zippers? This Installation Guide Might Surprise You

- Why Does Your Seam Ripper Have a Red Ball? Discover Its Purpose!

- Topstitching Troubles? This Simple Trick Will Turn It Around Instantly!

- How to Sew Shirring: A Step-by-Step Guide to Elastic Thread Gathering

- Are Self-Threading Needles Really Useful?

- Amazon Spring Sale: Best Choices