In this guide, I am focusing on different types of threads for sewing. There are many types of sewing threads. How many? Well, it’s hard to say but I would guess the number is in high hundreds.

Most of the time we hear that “more is better”. A greater selection means better choices for every operation, better quality because you can compare reviews, etc. But sometimes “more” isn’t necessarily better, sometimes it’s confusing and overwhelming.

A printable version of this article which includes the pattern is available in my Etsy shop or my my site shop.

Let me explain: if I have two threads, one thick, one thin, then the choice is simple. What if I have 1000? Have you seen the fabric shops lately? Look at the image below.

Note: Some of the links on this page are affiliate links. This means I will receive a commission if you order a product through one of my links. I only recommend products I believe in and use myself.

Do you see the literally thousands of threads on those racks? How do you choose? Is there a difference between them? Do I need to take into account the type of garment that I make? What about the fabric? Ok, does the type of sewing machine I use to make any difference? What if I sew by hand? Or if I sew leather or vinyl?

Attention! If you like the video format, at the bottom of this post, look for a YouTube video Thread Secrets where you will find really helpful information on … well, thread secrets! For a more complete picture, I recommend exploring both versions.

All these are valid questions and in time as an experienced user, you will learn about different types of threads and their uses. Problem is, that threads change. What was 25 years ago, is no longer true today, and if the trend continues, 15 years from now we will see a completely different picture.

For example, only 5 years ago the stretchable thread was not available for the regular sewing machine (it was available for sergers only). Today we have Eloflex which is excellent for sewing knit fabric on a home sewing machine.

So no matter how experienced you are, you really need to keep up with the changes!

This tutorial will try to help organize ideas and present alternatives for the user and it’s intended as a guide to help save time and effort when selecting a thread for a sewing project.

Thread construction methods

There are three main categories of threads based on their construction method:

1. Spun thread. This is your regular thread, the most widely used thread, and can be made with either natural or artificial fibers. Spun polyester is accepted as the best in this category, for the same thickness it’s generally stronger than cotton.

The fibers are spun into yarn (the same old process my great-grandmother was doing at home), then multiple strands are twisted together.

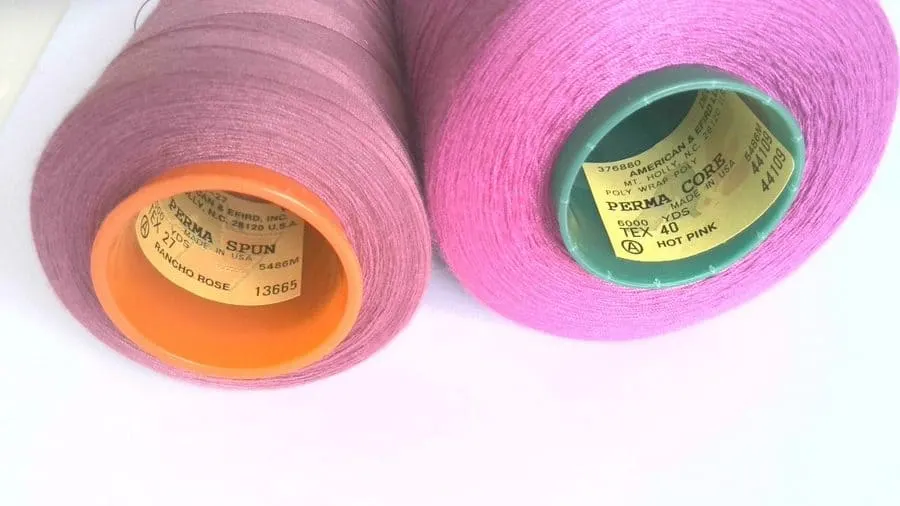

2. Corespun thread (sometimes also called poly-wrapped poly core or Perma core): the thread has an inner core made out of a single filament of polyester around which regular spun fibers are wrapped. Because of the filament core, this thread is stronger than the regular thread and isn’t common for regular home use but it’s used for high-speed sewing.

3. Filament or monofilament thread is made out of a long filament, as the name suggests; usually polyester.

There is no spinning and no yarn involved here, the thread is one long strand. If you want to think of a filament thread, think about a fishing line – the difference is that the fishing line isn’t polyester and is thicker, but the principle is the same.

One of the most popular monofilament threads is the“invisible” thread, which isn’t really invisible, but it’s very thin and can be hidden easily.

Some metallic threads are another very good example of filament thread. Because the filament thread is inherently shiny (no individual fibers), it’s also used in embroidery.

When two or more monofilament strands are twisted together we get a multifilament thread that is very strong and used in special applications like shoemaking or drapery.

There are other construction methods for specialized threads, for example, the bonded thread where a resin coat is applied on the thread to enhance its resistance, or the textured thread which is a thread that has been treated mechanically to obtain a stretchy, wooly thread.

Fiber contents

The thread can also be categorized by its fiber contents: natural fibers (cotton, silk, wool), artificial fibers (polyester, nylon), or (sometimes) a mixture of natural and artificial fibers. The most common materials used are cotton, polyester, nylon, rayon, and some specialized types (metallic, glitter, etc.)

Cotton absorbs dyes well, and the mercerization process makes it even better at this; therefore, the thread is colorfast, resists light exposure, and can be used for both machine and hand sewing. Cotton thread is a prevalent choice for sewing natural cotton fabric and for quilting.

Polyester thread is the most common thread and is very versatile. Polyester thread comes in a great variety of colors and thicknesses, it’s stronger than cotton for the same thickness, it’s shinier and a little stretchy.

However polyester doesn’t absorb color well therefore colors have a tendency to run and fade, especially in sunlight. UV light also damages untreated polyester after prolonged exposure.

A special mention for spun polyester thread used in sergers. I have seen mentioned that it’s specially treated with a coating layer to resist high-speed sewing; I can’t comment on the coating issue, it may be or not, I simply don’t know. However, my empirical observation is that the spun polyester serger thread, which is usually sold in bigger cones, is, in fact, a thinner thread and not as strong as other polyester threads. I would not use the serger thread in a regular sewing machine.

One more important fact: polyester actually melts at high temperatures. So when ironing an item with a very hot iron try first on scrap because the hot iron might damage the thread and ruin your project (it actually happened to me).

Both cotton and polyester can be spun, and spun threads (especially lower quality threads) can shed fibers and that isn’t only an annoyance, it’s actually dangerous for your sewing machine. The lint will accumulate and in time will prevent the machine from working properly, it can obstruct vents and cause overheating.

Of course, lint will accumulate in the most hidden and very difficult to clean spot! It’s therefore very important to use high-quality threads, they shed less.

There is also a process for cotton thread (gassing, also called silk finish) that actually burns the excess lint off the thread after it’s spun resulting in a smoother finish and more lustrous appearance.

Nylon is another synthetic fiber. It’s used not so often as polyester since it’s more expensive. Nylon is more flexible and stretches more than polyester, it’s also more durable and wear-resistant but it has low UV resistance. Both polyester and nylon can cause allergies in people.

A special category of threads is rayon. While a natural substance at origin (wood), rayon is processed extensively until the thread is created so in my opinion, it’s on the same level as any other artificial fiber. Because rayon is not spun but rather extruded in filaments, the thread is naturally shiny and is used mostly in embroidery. It’s not a strong fiber and doesn’t wear the color well, rayon colors run quite easily.

The Silk thread is also worth mentioning. A very thin silk thread can be used to sew very delicate fabric without compromising the quality of seams. Also because it’s thin it blends easily with the fabric and stitches are not very obvious. For sewing delicate silk this thread is an absolute must. If you are interested in how to work with natural silk fabric check out my tutorial “Helpful tips to avoid frustration when sewing silk”.

Shiny threads (metallic, mylar) are often used for adding pizzazz to your creations. Threads in this category vary wildly in quality and in general the saying “you get what you pay for” holds here, cheaper threads tend to be lower quality.

A metallic thread that is poorly constructed has the tendency to snag and will actually bite into your sewing machine’s metallic parts, the metallic part is quite abrasive.

Good quality threads try to “hide” the metallic part in such a way that it doesn’t have direct contact with the thread guides or the needle. Both metallic thread and mylar will require you to be careful and probably lower the speed of sewing.

How is the thread measured?

There are a number of units that measure the weight of a thread, usually the weight per a certain unit of length. The most used systems are (there are others also, see Wiki explanation here https://en.wikipedia.org/wiki/Units_of_textile_measurement):

Weight: it shows how many kilometers of thread are needed to make 1kg. If the weight is 40, it takes a length of 40km to make 1kg of thread. The lower the number, the heavier the thread.

Denier (Den): it shows the weight in grams of 9km of thread (9000m). The higher the number, the heavier the thread. But as for me, I have never seen thread spools marked with Den number.

Tex: it’s the weight in grams of 1000m of thread (1km). Similar to denier, the higher the number, the heavier the thread.

But the funny thing is that the heavier thread (in weight I mean) doesn’t necessarily mean thicker thread. The thickness of the thread can be deceiving when you look at it. The thread weight depends on the density of the thread, and the fibers used. So threads are marked differently in Tex or Wt. numbers can have the same thickness.

Most of the time threads sold in fabric stores for home sewists don’t even have any marks about the thread size. At the same time, industrial threads are always marked with Tex. or Wt. number. But it depends on the brand also. For example, the American&Efird company marks its threads most of the time.

You can usually see a clear difference in thread thickness if you compare two spools of thread that are the same size. For example, in the image below you can see the same size spools but the spool to the left (with brown thread) has 110 yards of thread, and the spool to the right has 274 yards, and this tells us that the green thread is much thinner.

✅Related tutorial: Types of Sewing Machine Stitches: Unraveling the Mysteries of the Straight Stitch

Brands of sewing threads

Thread is one of the things where it really pays when buying a brand name, especially if you don’t use industrial quantities.

Names that I like (there are many others): Gutermann, Coats and Clark, American & Efird, Sulky, Superior, Madeira.

What you should definitely avoid at all costs? I don’t usually give advice because I feel that nobody is the holder of the absolute truth and what may be right for me, might be not-so-right for someone else, but I strongly feel that you should not do the following:

- Buy cheap no-name thread sold at dollar stores or other discount stores.

- Buy old threads of the type found in garage and estate sales without trying them individually, and even then, be cautious.

Why not dollar store threads? Simple. The cheap thread is linty, weak, will break, snag and shed in no time, and will in fact cause you a lot more in lost time and nerves than you would save in price. Not counting the sewing machine cleanup.

Why not estate/garage sale threads? Because they might have been stored improperly and have been in touch with moisture, therefore they might be moldy. Or dirty, dusty. Because they might be old and the color might be faded, or part of it might be faded to the point that the thread looks like it’s multicolored. Because older thread technology was not always on par with a modern one and modern fibers are better, especially polyester. There are exceptions, of course, some threads might be in excellent shape, but every spool must be judged individually.

I usually buy my sewing threads in 1000-yard spools because I find bigger cones awkward to use, difficult to store and even 1000 yards lasts a very long time.

I do have larger cones acquired in specialized shops for industrial sewing. I bought those because they are exceptionally strong but I found out that I don’t really have any use for that much thread. They don’t fit on the sewing machine (I need a special stand for them) and most of the time I find myself passing over these large cones and using a smaller one simply because it’s more convenient. Compared to fabric, the thread isn’t a major expense, and I found that the money savings are not worth the added trouble.

What threads to use in your sewing projects

All-purpose thread

When you go to a fabric store to buy threads you can see that the biggest thread rack is always called ALL PURPOSE THREAD. But I don’t actually see this name on thread spools very often. I found only one spool in my big collection of threads that has this writing. Most of the time you will find that’s written DUAL DUTY on this type of thread or just 100% polyester.

This is your daily thread, good to use for almost all projects and all situations. The keyword here is “almost”, because you will probably use it 9 times out of 10.

It’s made almost exclusively out of polyester or cotton-covered polyester and comes in all colors imaginable and a number of sizes, but the most common are weight 40 and 50. In fact, most of the time the weight isn’t even mentioned on the thread.

The few jobs for which this thread isn’t suitable are sewing very heavy fabric (denim, upholstery, decorator fabric), outdoor items that need to withstand direct sunlight/moisture, and very thin fabric (gauze, organza).

A special mention for sewing silk, I always prefer to use silk thread for silk fabric.

This thread is also not suitable for embroidery, use embroidery polyester, rayon, or silk for that.

In general, I prefer to match the fabric with the thread since they will be washed together and will suffer the same kind of wear. This, however, isn’t a strict rule, it’s mostly an empirical observation. But it makes sewing easier, I noticed (and I am not the only one) that it’s easier to set the tension on the sewing machine if the thread matches the material in both fiber and thickness.

I would like to remind you again that using polyester thread for items that will be pressed at high temperatures is problematic because polyester thread might melt. It happens more often than one would think!

Serger thread

Serger thread is also one variation of the all-purpose thread. Serger thread is generally thinner than regular thread because a serger seam has a lot of thread and would be bulky otherwise.

A serger seam is strong not necessarily because the thread is strong (it’s not stronger than regular thread), but also because of the inherent construction of the seam, the serger uses 3 or 4 threads to build the seam while a sewing machine uses only two.

Serger thread comes usually in larger cones, 3000 yards, or bigger, and I don’t recommend it for a regular sewing machine mostly because it leaves a lot of lint behind unless you buy very high-quality threads. Regular serger thread is mostly 100% polyester.

A notable mention for stretchy serger thread: wooly nylon (or textured nylon) was available for quite some time now and is used regularly in sergers for stretch fabric. This type of thread is stretchy not because it has elastic properties, but because it’s mechanically treated and under tension, it becomes thinner and longer without the individual fibers having many elastic properties.

This kind of thread can be used in a regular sewing machine also (in the bobbin ONLY) with special stretch zig-zag stitches.

✅ Related tutorial: Stretch thread for sewing

Quilting thread

There is a special quilting thread. Most quilters prefer to use cotton thread for quilting, especially since most quilts are made of cotton fabric. But the special quilting thread (at least what I have as a quilting thread) is usually cotton-covered polyester and it has a glace finish and much less lint because of this. It also has a lustrous appearance.

Embroidery thread

Embroidery thread is shiny, often thinner than regular all-purpose thread, and is usually rayon or polyester.

Cotton embroidery thread is manufactured and sold but I personally prefer not to use cotton in embroidery. Embroidery machines use a lot of stitches, many more than a regular sewing machine, and that will generate a lot of friction for the thread, and a lot of lint; and cotton thread is the king of lint.

Think about it: a very small 2”x2” (5cmx5cm) design may have 3000 to 5000 stitches; at a stitch length of 2.5mm this is a linear stitch of 7.5 to 12.5m! That is probably two to three times as much as a whole blouse, and we are talking a VERY small design here! I don’t even want to think of a design that uses 30000 to 50000 stitches.

There are many types of embroidery threads (different fibers, different thickness/weight, different brands, cones, and spools can have different shapes and sizes) and this is a very big topic for another article.

Let me show you how different embroidery threads can be. Check the image below: 15-weight thread!

Heavy duty thread

As the name says, the heavy-duty thread is designed to withstand high tension and wear and it’s generally thicker than regular all-purpose thread. It can be cotton, polyester, a combination of the two, or even nylon.

Depending on its exact destination it may have extra attributes, for example for outdoor use, may have been treated for UV protection, or for water resistance.

What do you use this thread for? Thick/heavyweight fabric, outdoor equipment, garments, sports equipment, luggage, bags, curtains, etc.

Bonded nylon thread

Bonded nylon thread is a good example of a heavy-duty thread. It’s also called “waxed thread” sometimes because of the resin coating that makes it impermeable to water and increases its durability.

The resin doesn’t have to be wax and probably currently it’s not, but this is how the thread started.

It’s used mostly in industrial applications where water impermeability and strength are important (shoes, luggage) and probably only on special machines because otherwise the wax/resin would clog the machine immediately.

In the image below you can see bonded nylon thread which is a really heavy-duty thread. I can’t even break it by hand, it’s that strong.

Another type of bonded thread is known under the name “button or carpet thread” and it’s in fact another variation of the heavy-duty thread, also used only for hand sewing because the wax doesn’t behave well in a sewing machine. Never use any kind of bonded thread in a home sewing machine! If you do, your sewing machine repair service will love you!

Upholstery thread

Upholstery thread is in fact a type of heavy-duty thread and it’s also a thick/heavy thread; nylon is sometimes preferred for upholstery thread. The upholstery thread may see exceptional heavy wear in certain situations. Think about a seam for a couch that will need to last 10, 20, or more years despite being used daily. Personally, I have used the upholstery thread very little because few projects require that extreme resistance.

Jean/denim thread

Jean/denim thread is another type of heavy-duty thread. What makes it special? Probably the color? This is why I used it, it’s difficult to find the exact match for your jeans otherwise.

Invisible thread

Invisible thread is in fact a monofilament thread and it’s not really invisible, it’s just very difficult to see on the fabric because it’s very thin and it’s also transparent.

For dark fabrics, a smoky version is made with some added color in the material of the thread.

This thread is unraveling very easily from the spool and you have to be careful when manipulating it. A special needle for the metallic thread is recommended for this.

Elastic thread

Elastic thread is used for gathering or shirring the material; this type of thread isn’t merely stretchy, it’s real thin elastic and sewing with it is really different than sewing with regular thread. You only use this thread in the bobbin and regular thread for the needle.

Stretch thread

Stretch thread to use mostly in sergers is wooly nylon (or textured nylon). But now we have a stretch thread for a regular sewing machine. It’s a newer kind of thread and I personally use only one brand: Eloflex, by Coats & Clark. I like to use this thread, it’s very useful in certain situations and I felt it deserves its own article, so I wrote a review of this thread.

But I also have a Fujix knit sewing thread that is stretchable but I didn’t use it yet so I can’t say anything about this thread.

Fusible thread

Did you know that a fusible thread exists? Yes, it does. It is made out of nylon and it melts at a relatively low temperature, exactly like the regular fusible interfacing.

It has the advantage that it forms a continuous bond between the two pieces of fabric, therefore, preventing puckering or shifting of the material when further processed.

You can even use the thread without stitching to hold trims or fabric in place. Just sandwich the thread between two pieces of fabric and press with an iron. The adhesive will melt and the pieces of fabric will be glued to each other.

It can be used to sew zippers in place, attach trims and binding, make pleats, etc.

I have seen other usages also, mainly as an accessory to art constructions, where the design is sewn into a piece of fabric then a metallic or colored paper is placed on top and ironed; the thread melts and the colored/metallic part of the paper sticks to the fabric permanently, creating the design.

You can read more about using this thread in Threads magazine at this link.

Wash-away thread (disappearing thread)

Another curiosity, very useful for temporary basting: disappearing thread. It’s in fact a water-soluble thread and may be used wherever a temporary seam is necessary.

In order to remove the thread, you need to submerge the seam (or the whole item) in water, so it can be used only with fabrics that will not be harmed by water or steam.

It looks just like a regular thread. I wound a bobbin with it and threaded my sewing machine with it. It made nice stitches. But after I put water on it – it disappeared!

No more frustration of removing basting stitches or sewing and quilting over your basting thread! It disappears without a trace.

It’s good both for machine basting and for hand basting. You can baste hems, pleats, zippers, baste a garment for fitting, baste appliques, pockets, etc.

Or you can sew a bathing suit for somebody you really don’t like. Just kidding.

Lifetime thread

I have to mention another thread, even if I didn’t use it and I probably never will: have you ever heard about the “lifetime thread”? Yes, it exists! It resists everything, direct sunlight, UV exposure, extreme temperatures, harsh cleaning agents, snow, water, rot – in a word, indestructible.

The manufacturer (Sailrite) even says so: “it will outlast your fabric”. Isn’t modern science wonderful? But it’s pricey, on the manufacturer’s page I found it side by side with an extra strength bonded nylon Coats thread which was priced at $2.95 for 250 yards; this lifetime thread was a cool $76 for 800 yards! But I guess for certain applications it may make sense.

So here is my YouTube video. Check this out if you like to see Thread Secrets.

There are many places where you can buy thread, and I recommend you wait until the right bundle or sale. Sales are frequent and even if you do not need the thread right at that moment, you should always have a ready supply of thread since there is no sewing without it!

Also, remember that embroidery thread is usually not suitable for regular sewing, so buy the right kind of thread for each project. The reverse is also true: sewing thread is not always suitable for embroidery.

Did you find this guide helpful? If so, save this pin (see below) on your sewing board so you can come to this tutorial later when you need it, and follow me on Pinterest for more tips, tutorials, and inspiration!

latest posts

- Ever Tried This on Your Serger? This Differential Feed Feature Will Amaze You

- Ditch My Sewing Machine? Not in This Lifetime!

- Adorable DIY Needle Book | Easy Tutorial for Beginners

- Master the Seam Ripper: Your Ultimate Guide to Precision Stitch Removal

- Think You Know Zippers? This Installation Guide Might Surprise You

- Why Does Your Seam Ripper Have a Red Ball? Discover Its Purpose!

- Topstitching Troubles? This Simple Trick Will Turn It Around Instantly!

- How to Sew Shirring: A Step-by-Step Guide to Elastic Thread Gathering

- Are Self-Threading Needles Really Useful?