If you are considering purchasing a sewing machine or have a basic sewing machine that you want to upgrade, it’s worth your time to consider several advanced sewing machine features that can transform your sewing experience. Here are my top recommendations.

I started learning to sew on an old treadle Singer that had been my grandmother’s faithful companion. It wasn’t even electric, but that didn’t stop her from creating the most wonderful pieces with it.

The machine was limited to a straight stitch, which was standard at the time. I dreamt of a machine that could at least do a zigzag stitch, so I wouldn’t need to finish raw edges and make buttonholes by hand.

Fast forward to today, and I own a sewing machine that cost more than my first car. It’s a technological wonder, boasting more features than I could have ever imagined. It has two computers built-in and thousands of stitches. This machine can do everything I can imagine and more. It’s a testament to just how much sewing machines have changed.

Gone are the days of being limited to simple stitches and manual operations. As I marvel at the capabilities of my current sewing machine, it’s clear that innovation has redefined what we can achieve with these machines.

Now, let me guide you through the advanced features that make modern sewing machines not just tools, but gateways to endless creativity.

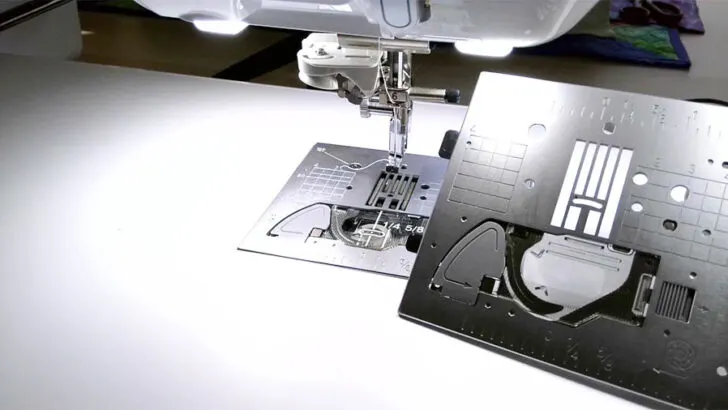

#1. Interchangeable Needle Plates

Interchangeable needle plates can transform your machine’s adaptability and performance.

The significance of having two different needle plates – one with a wide hole and another with a small hole – lies in their ability to optimize the machine’s performance for specific tasks.

The wide hole needle plate is ideal for zigzag stitches, buttonhole stitches, and decorative stitches, that move the needle side to side. It provides the necessary space for the needle to move freely without any restrictions, ensuring the stitches are formed correctly and the fabric feeds smoothly.

The wide hole needle plate is also essential for the successful use of a twin needle. A twin needle creates two parallel lines of stitching simultaneously, which requires additional horizontal needle movement. A wide hole needle plate accommodates this movement.

On the other hand, the small hole needle plate is designed for precision in straight stitching. When working with lightweight or delicate fabrics, or when precision is paramount, such as in quilting or topstitching, the small hole supports the fabric closely around the needle. This also minimizes the possibility of fabric being pulled into the needle plate, which can cause puckering or damage to the material.

Some advanced sewing machines with interchangeable needle plates feature a quick and easy swap mechanism. This allows sewists to change the plates without the need for a screwdriver so you can easily switch between sewing tasks that require different needle plates.

Advanced sewing machines often come equipped with sensors that recognize which needle plate is installed. This smart feature can prevent the selection of stitches that are not compatible with the currently installed plate, thereby protecting the fabric, needle, and machine from potential damage.

For an in-depth exploration of interchangeable needle plates and their impact on your sewing projects, be sure to check out my detailed tutorial, Types of Sewing Machine Stitches: Unraveling the Mysteries of the Straight Stitch.

2. Automatic Thread Cutter

An automatic thread cutter is one of my favorite features to save time and streamline my workflow. Some sewists might even call it a total luxury!

It’s a mechanism built into some sewing machines that allows sewists to quickly and neatly trim the top and bottom threads with a simple press of a button. This button:

On select models, I’ve found pressing the heel of the foot pedal can activate this feature, too, providing a hands-free experience.

The automatic thread cutter boosts sewing productivity by boosting efficiency, helping you finish projects faster. It cuts threads neatly without the need to find or use your scissors.

It can also help with thread conservation. By consistently snipping the thread at just the right length, it minimizes waste, which can add up to significant savings over time, especially when using expensive or specialty threads.

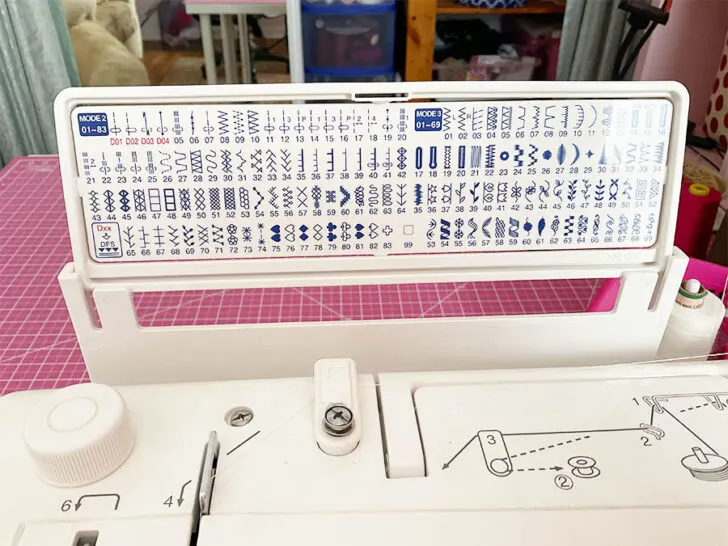

3. Variety Of Stitch Options

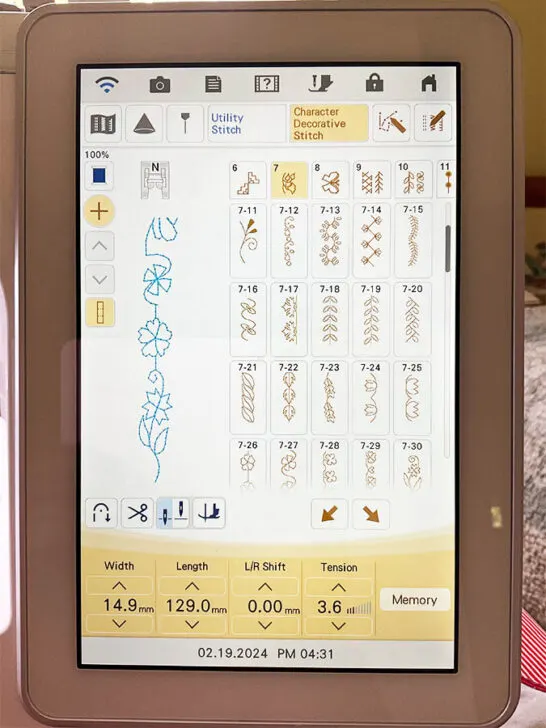

Advanced sewing machines offer an exciting range of stitches, from basic utility stitches to intricate decorative ones. This variety allows you to tackle everything from simple repairs to elaborate embroidery projects.

In my sewing practice, the most frequently used stitches are the buttonhole stitches, stretch stitches, and blind hem stitches. These stitches are essential for constructing professional-looking garments.

Given that buttons are a common fastener in clothing, having a machine that can produce consistent one step buttonholes is invaluable.

Stretch stitches are necessary when working with knit fabrics or any material with elasticity. These stitches allow the seams to stretch with the fabric, preventing the threads from snapping when the material is pulled or worn.

Blind hem stitches are my go-to for hemming projects where the stitch needs to be invisible or nearly invisible on the right side of the fabric. This stitch is perfect for creating nice hems on skirts, pants, and sleeves.

While I don’t often use decorative stitches, it’s comforting to know they’re available on my machine for when a project calls for a special touch. They can add unique details to a project, transforming simple items into custom, one-of-a-kind pieces whenever I decide to utilize them.

To learn more about various stitches machines can do these days, check out my article, A Guide To Different Types Of Sewing Machine Stitches.

4. Presser Foot Pressure Adjustment

The Presser foot pressure adjustment is another indispensable feature on my sewing machines.

Presser foot pressure is the force exerted by the presser foot onto the fabric as it is fed through the machine. This pressure keeps the fabric stable against the feed dogs, which move the fabric along during stitching.

If the pressure is too high, it can stretch or damage fabrics. If it’s too low, fabrics might not feed through consistently, resulting in uneven stitches. Adjusting to the correct pressure ensures your fabric feeds through smoothly, preventing puckering or stretching.

The key is to adjust the presser foot pressure according to the fabric’s weight and characteristics to ensure optimal sewing conditions for each specific project.

When I work with delicate lightweight fabrics, I reduce the presser foot pressure to avoid puckering or dragging, ensuring the material feeds through the machine smoothly without being stretched or damaged. A reduced pressure allows the fabric to feed through the machine gently, which is especially important for fabrics like chiffons, georgette, voile, and other fine materials that can be easily damaged or distorted by excessive force.

When I sew with heavier or multi-layered fabrics, increasing the pressure helps to keep the material stable and prevents it from shifting, which is necessary for maintaining consistent seam quality.

Some advanced machines offer automatic presser foot pressure adjustment, which detects the fabric thickness and adjusts accordingly, providing optimal performance without the need for manual intervention.

5. Lighting

The advanced lighting in modern sewing machines provides a clearer view of the sewing area, improves accuracy, and enhances overall user comfort, which is why it’s such an important feature in today’s sewing technology.

Lighting in modern sewing machines has seen significant improvements over previous generations. The most notable difference is the use of LED lights, which provide a brighter, more natural light compared to the dimmer incandescent bulbs found in older machines.

This improved lighting helps reduce eye strain, allowing for longer sewing sessions without discomfort. Good lighting is essential when threading the machine, working with intricate stitches, or sewing with dark materials where visibility is key to maintaining accuracy.

LED lights offer a more consistent light source that illuminates the entire work area evenly, without casting shadows that can affect how you perceive colors and details.

Another advantage of LED lighting is its longevity and efficiency. LEDs last much longer than traditional bulbs and consume less energy, making them more sustainable and cost-effective in the long run. They also generate less heat, which makes the sewing environment more comfortable.

✅ Related tutorial: Sustainable Sewing: Eco-Friendly Techniques For The Modern Sewist

I remember working on machines that had poor lighting, and the difference in my accuracy and overall enjoyment levels between then and now is like night and day.

6. Free Arm Capability

A free arm is essentially a narrow working area extending from the main body of the sewing machine that allows sewists to remove a portion of the sewing machine’s flatbed. It’s ideal for sewing tubular-shaped pieces because you can move and rotate the fabric freely, reducing unnecessary fabric bunching.

Items such as sleeves, pant hems, and children’s clothing can be difficult to manage on a standard sewing machine, but a free arm makes all of these simple.

Check out my tutorial on How To Use A Free-Arm Sewing Machine to learn more about it and see it in action.

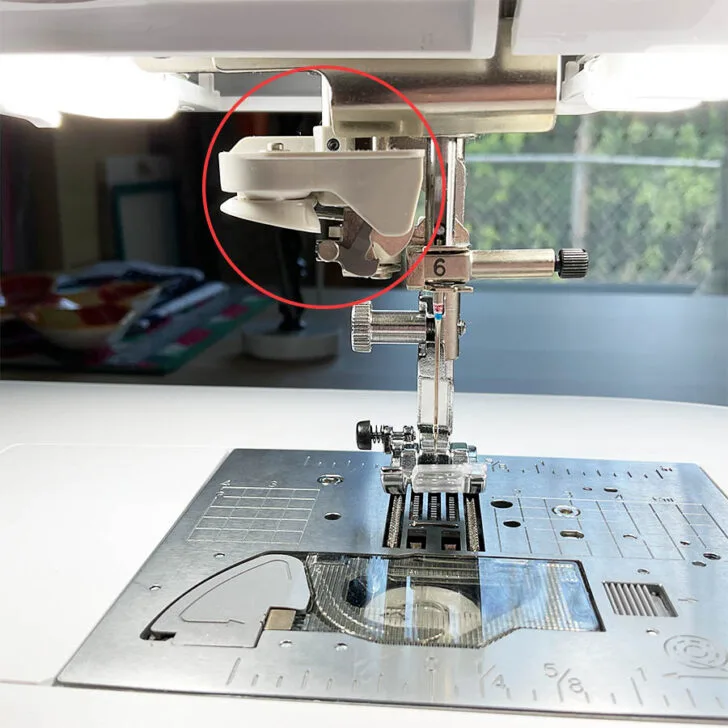

7. Knee Lifter

A knee lifter is a lever that lets you raise and lower the presser foot with your knee, leaving your hands free to handle the fabric as you sew. It connects to the sewing machine through a mechanism typically found on the lower front side.

By simply adjusting your knee position against the lever, you can effortlessly adjust the presser foot to pivot or reposition your fabric without stopping your workflow.

Initially, I put off using it, sticking to the more familiar method of pressing a button. But once I decided to give the knee lifter a try, I was taken aback by the convenience it offered. Now I find myself wondering, why didn’t I use this before?

The knee lifter allows me to raise and lower the presser foot without using my hands. It’s especially useful when I need both hands to maneuver the fabric.

I’ve come to appreciate the knee lifter. It’s one of those features that once you start using, you can’t imagine how you managed without it.

8. Automatic Needle Threader

I used to squint and huff, trying to coax a stubborn thread through the eye of a needle, especially with tired eyes or in poor light.

But then, along came the automatic needle threader. With a simple button or pull of a lever, it grabs the thread and slips it through the needle’s eye.

No more do I need to start my sewing projects with a deep breath and a prayer to the sewing gods. The automatic needle threader has turned what was once a test of patience into a simple, push-button solution. And why everything in life isn’t equipped with one!

✅ Related tutorial: How to thread a needle on a sewing machine

9. Adjustable Speed Control

Changing speed control settings on a sewing machine simply involves adjusting sliders or buttons to the rate that best fits your project and experience.

It allows me to vary the sewing speed, giving me control over how fast or slow the fabric is fed through the machine. When I’m working on something that requires a high level of precision I sew slower. But when I’m working on long, straight seams or I’m under a time crunch, I ramp up the speed.

It also helps manage different types of fabrics. Delicate fabrics may need a slower pace to prevent damage, while sturdy materials sometimes require a faster stitch.

10. Extension Table

An extension table is an attachment you can connect to your sewing machine to expand your flat working surface. This is especially handy when working on big projects like quilts, curtains, or gowns.

One of the main reasons I like the extension table is the support it offers. It holds the weight of the fabric, preventing it from pulling or dragging during sewing. The larger flat surface makes guiding the fabric smoothly and evenly through the machine much easier.

The added flat surface is also excellent for keeping everything level.

Quilting particularly benefits from an extension table since it provides the space needed to handle multiple layers of a quilt sandwich effectively without the edges falling off the side of the machine, which can lead to uneven stitches or misalignments.

11. Twin Needle Capability

A twin needle consists of two needles connected to a single shank, allowing sewists to create two rows of stitching at the same time, and provides several benefits:

- Durability – The two lines of stitching provide a reinforced structure for seams.

- Flexibility – When hemming knits, it allows the fabric to retain its elasticity, preventing broken stitches.

- Aesthetics – It creates a professional-looking hem or a decorative element that mimics the look of coverstitching.

Here are some examples of common applications:

- Hemming Knits – Achieving stretchy hems that don’t snap as the fabric expands.

- Pintucks – Adding delicate raised lines to garments and home decor.

- Topstitching – Producing parallel lines of stitching on cuffs, collars, and other edges.

- Decorative Stitching – Experimenting with various thread colors and types can give my project a unique design element.

Check out my post on Twin needle sewing machine – everything you need to know about sewing with a twin needle to learn more about using twin needles.

12. Built-In Accessory Storage

It’s very convenient to have a designated spot for my sewing machine accessories. Having a nifty compartment within easy reach keeps bobbins, needles, and seam rippers readily available but out of the way so your workspace remains clutter-free. It’s a small feature with a big impact!

13. Programmable Needle Up/Down

With this feature, I can pre-set my machine to stop with the needle either in the highest up position or fully down in the fabric at the end of each stitch.

Having the needle stop in the down position is very useful when I’m working on corners or curves that require pivoting. The fabric stays in place, anchored by the needle, which allows for smooth and accurate turns. This is a huge time-saver. Or, for example, when inserting zippers, setting the needle to stop in the down position keeps the fabric stable between adjustments.

Setting the needle to stop in the up position is ideal when I need to remove the fabric quickly after sewing or when I’m chain piecing and need to swiftly move from one piece to the next without delays.

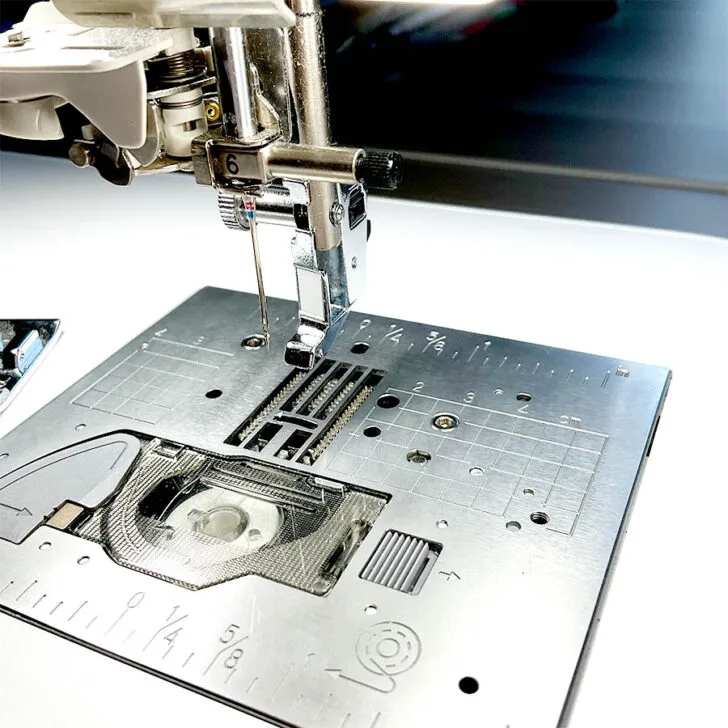

14. Drop Feed For Free-Motion Quilting

The feed dogs are tiny, teeth-like mechanisms under the sewing machine’s needle plate area. When engaged, they move the fabric through the machine in a uniform manner for regular sewing.

The drop feed feature provides the option to lower the feed dogs and disable that movement. This feature is used for free-motion sewing because it removes the machine’s grip on the fabric, allowing the flexibility to move the material in any direction.

15. Variable Needle Positions

I often find myself adjusting the needle position when I need to sew with exact seam allowances. By shifting the needle to the left or right, I can align the edge of the fabric with the presser foot edge and use the foot as a guide. This ensures my stitches are where they’re supposed to be, providing that straight line I want.

It’s a feature that also comes in handy for topstitching because I can tweak the needle position to achieve the perfect distance from the edge.

What’s more, variable needle positions can be a sewist’s secret to success when installing zippers. The feature allows you to get close to the zipper teeth without the presser foot interfering.

✅ Related tutorial: The Invisible Zipper Foot: What It Is And How To Use It

16. Customizable User Settings

Imagine adjusting your sewing machine to the perfect stitch settings for a project and then, with a mere button click, saving those settings for future use. Sounds dreamy, right? Well, with customizable user settings, this dream is just a button push away.

When you use this feature, you can ditch the headache of jotting down notes, trying to remember the exact tension or stitch length, or manually adjusting settings every time you start a project.

With this feature, you can store your go-to stitch width, length, and pattern so they’re ready at the push of a button and set the machine to remember specific settings you’ve used for different fabrics.

For example, I created this decorative stitch on my machine. It’s a combination of four different decorative stitches from the machine’s vast selection. I saved it into my machine’s memory. Now, whenever I wish to add this stitch to a project, I just press the memory button, and voilà – all my saved stitches are there at my fingertips, ready to be used. There’s no need for me to go through the process of creating this stitch combination each time I want to use it.

17. Laser Guide

A laser guide on a sewing machine might seem like something out of a sci-fi movie, but it’s real and incredibly useful.

This feature projects a sharp, straight line (or even two lines of different colors) directly onto your fabric, guiding your sewing for unbeatable topstitching and seam accuracy.

This feature is particularly handy for sewing long, straight seams or when I use fabrics with stripes or plaids. It’s also a great help for straight line quilting.

✅ Related tutorial: The Basics of Straight Line Quilting

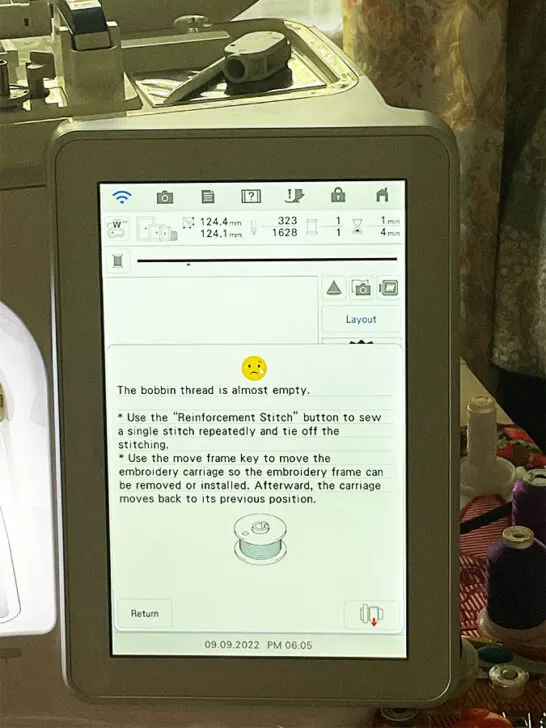

18. Bobbin Thread Sensor

The bobbin thread sensor is a must-have for uninterrupted sewing. Imagine you’re deeply focused on a project, and suddenly, your thread runs out. So annoying! This feature prevents that by alerting you before the thread is completely gone, allowing for a seamless transition to a new bobbin.

This not only saves time but avoids the hassle and frustration of unwanted sewing pauses to improve efficiency and deliver professional-looking results.

If you’re curious to see this feature in action and learn why it’s my personal favorite, I invite you to watch my short YouTube video – What is the most desired feature of a sewing machine.

19. Touchscreen Interface

Touchscreen interfaces on modern sewing machines make selecting stitches and making adjustments as easy as tapping a screen. No more turning dials or pushing buttons to choose your stitch or adjust its length or width.

I have to admit, the leap to touchscreen controls on sewing machines was reminiscent of upgrading from a flip phone to a smartphone because it made all those settings feel more intuitive.

This feature also opens up a visual menu of stitches, making it easier to explore and use the machine’s full range of capabilities.

If you’re considering taking the plunge on a new sewing machine, I hope you’ll find one (or more) of these advanced sewing machine features helpful and worth the splurge on cost!

What are some advanced features on your sewing machine that I haven’t mentioned yet? Share the hidden gems of your sewing equipment in the comments!

No time to read now?

No worries! Save this image on Pinterest to read it later!

latest posts

- Knot a Problem: Easy Ways to Secure Short Thread Ends

- Ever Tried This on Your Serger? This Differential Feed Feature Will Amaze You

- Ditch My Sewing Machine? Not in This Lifetime!

- Adorable DIY Needle Book | Easy Tutorial for Beginners

- Master the Seam Ripper: Your Ultimate Guide to Precision Stitch Removal

- Think You Know Zippers? This Installation Guide Might Surprise You

- Why Does Your Seam Ripper Have a Red Ball? Discover Its Purpose!

- Topstitching Troubles? This Simple Trick Will Turn It Around Instantly!

- How to Sew Shirring: A Step-by-Step Guide to Elastic Thread Gathering